Refinement

We take great care in refining the labels. We are aware of how important the finishing of the labels is. It should give your products a stamp of uniqueness and exclusivity. It's a way to differentiate yourself from the competition and draw the eyes of the end customer to your products even more. There are many ways to highlight and underline the uniqueness of your products.

Hot Embossing

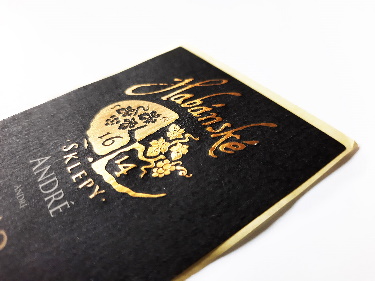

Hot embossing is a technology where, at elevated temperatures and pressure, a layer of foil is transferred to the desired material. On the motif, the adhesive, (which is applied to the embossing foil), is thermally activated and the foil is then permanently glued to the material. One of the advantages of hot embossing is the possibility to apply it to many different types of materials. For hot embossing, we offer a wide range of foils in every possible color. Thanks to this, we are able to create very special embossing, e.g., holographic foils, customized foils with their own motif, or wiping embossing. Hot embossing can be combined with any print, including screen printing Exciting and eye-catching looks are possible using embossing with UV screen printing vanish.

Hot embossing gives the labels a rich, luxurious appearance and gives the impression of exclusivity. This type of printing is especially suitable for the packaging of special editions, luxury cosmetics, expensive assortments of chocolates, food specialties, or alcohol.

Cold Embossing

Cold embossing is applied using a flexographic printer, a block, glue, and embossing foil. The embossing foil does not contain glue, instead it is applied separately using a flexographic sewer. This process, unlike hot embossing, does not involve heat, hence the name cold embossing. Glue is first applied to the material, and then pigment from the film is imprinted on the areas where the glue is. Cold embossing enables the possibility of printing on foil which has already been applied to create metallic effects. It is possible to further print on this film to create interesting effects and combinations. This is especially valuable for graphics and opens up a range of possibilities and a huge space for creativity. Gold and silver paint or foil are mainly used for cold embossing. Printing silver foil with yellow creates gold foil, so both silver and gold cold embossing are possible. Other shades are considered non-standard, and therefore such requests involve testing the film, which requires additional time for the completion of such orders. Please note that cold embossing does not replace hot embossing as they are two completely different technologies.

Embos

Embos is a type of relief embossing where a plastic effect is created on the label using a block. This method involves pushing the material, including its base, upwards, which creates a relief or plastic effect of the raised motif. This type of printing can also be called blind printing. It is possible to combine Embos with printing or hot embossing. This label printing technique is best suited for natural and structured materials, on which the extruded reliefs stand out the most.