Printing technologies

LABEL design a.s. is the only company on the market to offer the widest range of printing technologies and their combinations. Our production department is ready to translate even the most complex idea into reality. We can recommend a suitable combination of technologies so that the price and the resulting effect always remain in balance. For a better indication, we can present you with a number of samples of our work.

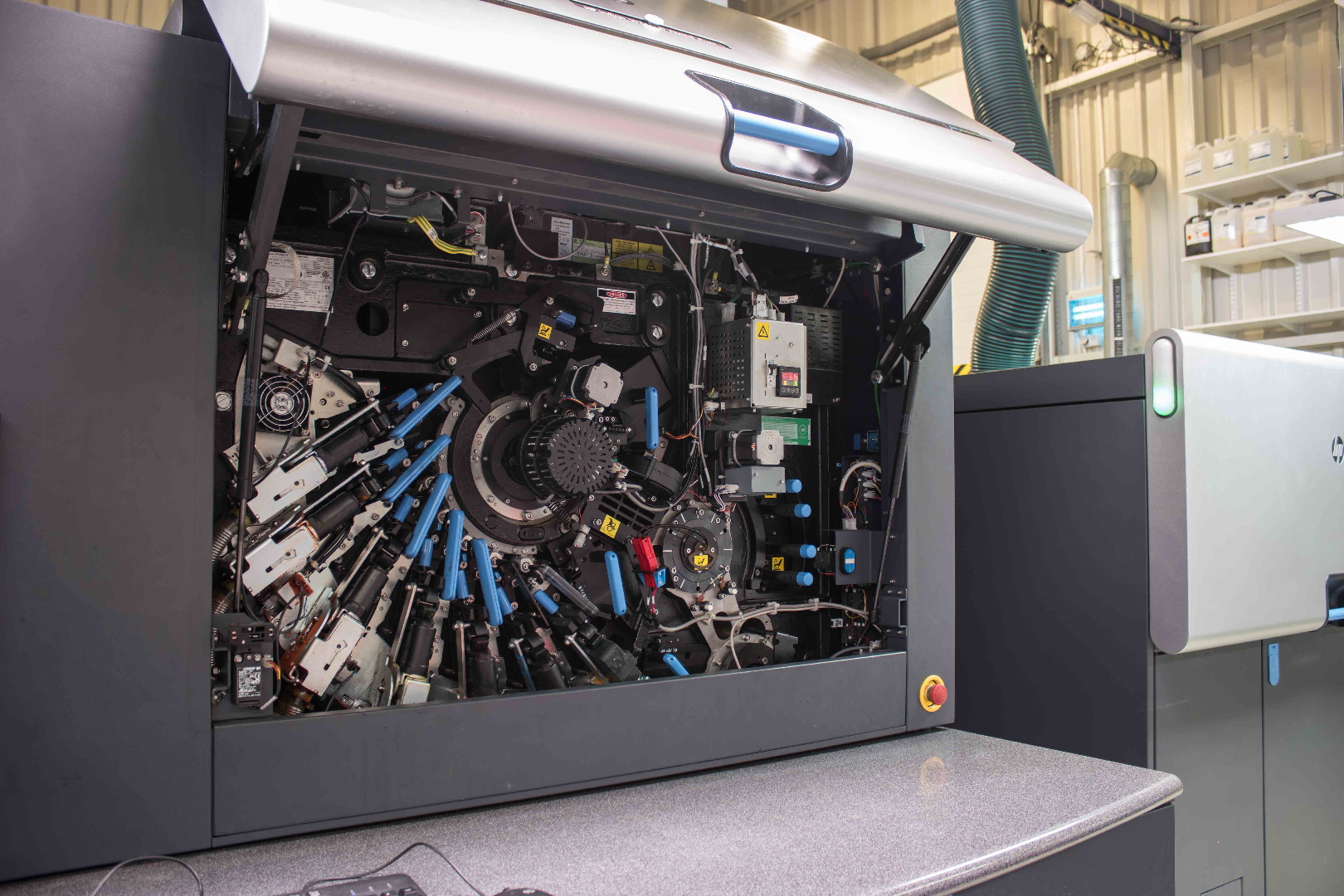

Digital printing

We offer two different digital printing technologies. HP Indigo printing machines are known as digital offset printing machines due to their high print quality. The Domino injection machine offers higher color application with a distinct final color effect. All of the machines in the digital section are suitable for short orders of all types of products. With their speed and stability, they are the answer to today’s requirements. Variable data can be processed for printing, which will be suitably incorporated directly into the graphics.

UV OFfSET printing

The highest quality printing for complex graphic labels with photographs, fine transition raster, or small negative fonts. A clear alternative for long orders compared to digital offset. It is recommended for printing products processed in CMYK colors, or with one additional color.

Flexographic printing

This is most common type of printing, and not only for self-adhesive labels, with a wide range of applications. Up to eight colors can be printed in combination on both the front and reverse side. It is more efficient for longer orders. Based on the customer’s requirements, machines with this technology can be supplemented by cold stamping, layering of materials, printing on glue, and final archiving.

UV screen printing

V screen printing provides high ink application and perfect coverage. The print is distinctive and plastic. It is mainly used in combination with other technologies. It is used for opaque white when printing on transparent materials.

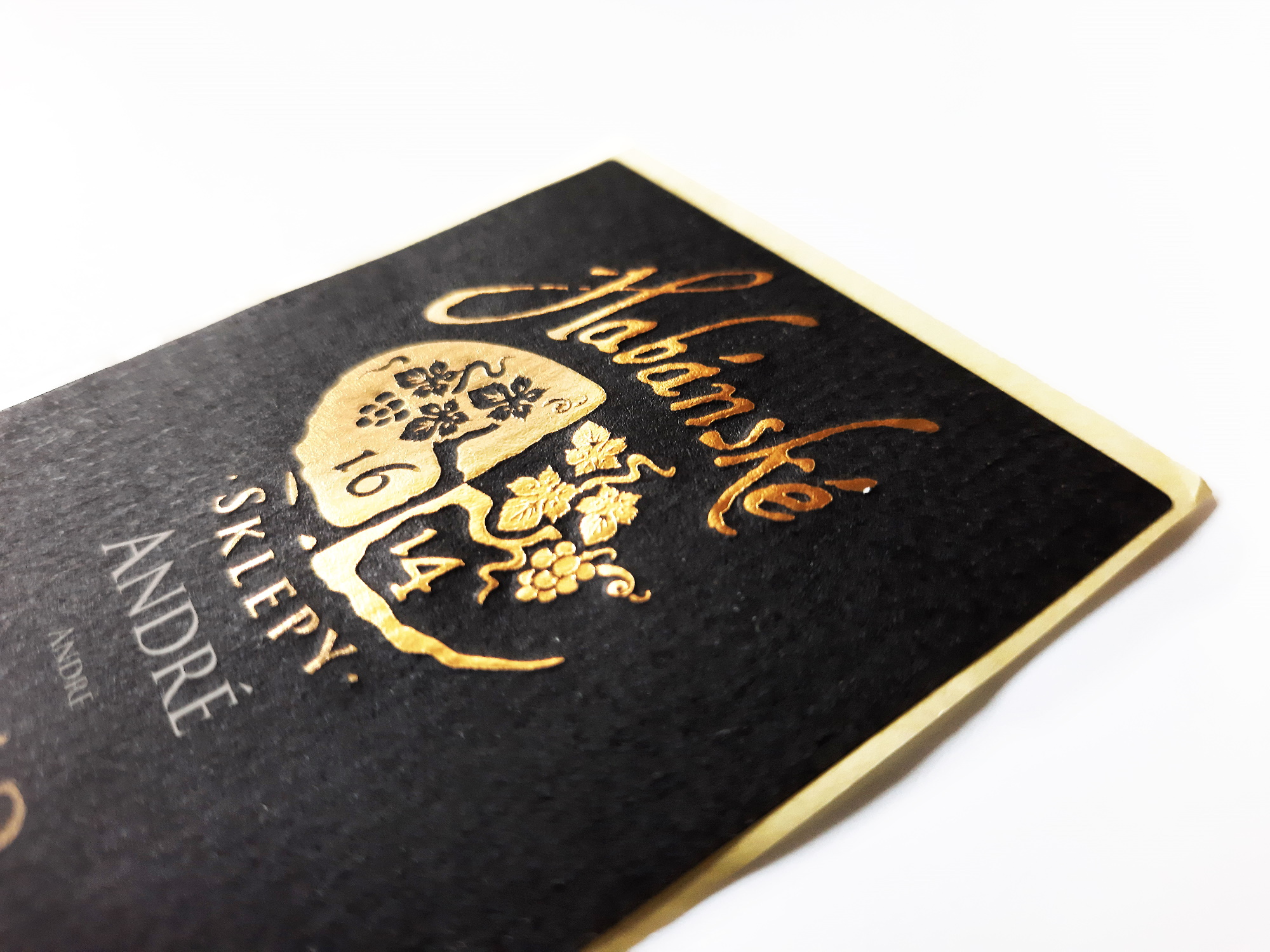

HoT stamping

Hot stamping adds exclusivity to labels. It is mostly used in combination with classic printing. Embossing foils can be gold and silver, but also colored or holographic. A specialty is scratch-off hot stamping foil.

embossing

Embossing is created by extruding a material through an embossing mold. This is suitable for highlighting graphics by providing plasticity to the label.

numbering

Personalization of products is performed as a finishing operation by ink-jet or thermal transfer printing technologies. It is used, for example, for competitions, registration, and personalization of labels.

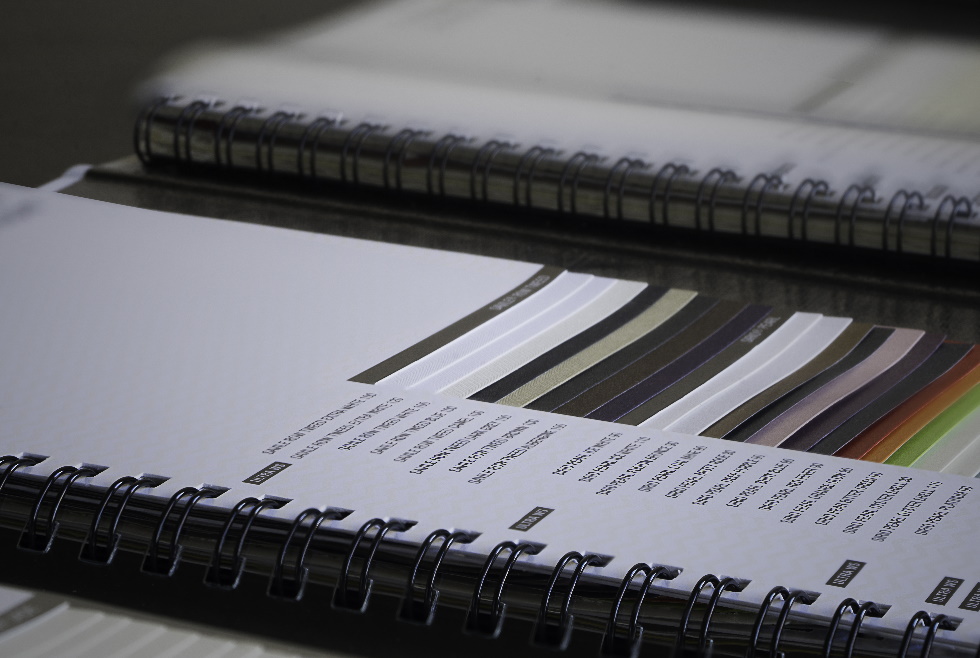

Materials

The selection of a suitable material, glue and colors for printing will ensure the correct functionality of the labels on the product, but also the achievement of the best design effect. It is important to know what packaging the product is intended for, how it will be applied, and in what environment it will be stored. For non-standard use, we can select specific materials and colors in cooperation with our suppliers.

Materials

Paper labels are smooth or matte, reflective, metallized, imitation handmade paper, and more. Plastic labels are made of polyethylene, polypropylene, and other materials, mostly in both transparent and white versions. The surface treatment can be matt, glossy, or metallic. The selection of materials includes special ones, whose properties correspond to the specified requirements. We can also offer our customers a wide range of ecological materials. In cooperation with our suppliers, we will be happy to recommend a suitable type of material for your specific use.

colors and varnishes

The basic color scale is given by the PANTONE sampler. The chosen printing technology has a great influence on the resulting color. In addition to standard colors, it is possible to use reflective, matt, scratch-off, or heat-responsive colors. The basic property of a varnish is the surface protection and highlighting of the print. Varnish can also be printed partially to highlight details. We can also use special varnishes with a scent, metallic effect, bubbles, or embossed.

DTP

From the very beginning of the operation of the company, the DTP studio was necessary for the high-quality preparation of documents for printing, and the efficient processing of orders for production. Data from our customers is processed with the knowledge of all the available printing technologies in production. Pre-press preparation of data takes place in close cooperation with the technology department who provide consultation on the editing of data for specific technologies.

We also offer customers, graphic designers, and graphic studios, preliminary consultation with possible recommendations for data editing in terms of the printing technology expected to be used.

Our established automated pre-press workflow helps us to increase the efficiency of data processing in the DTP studio. However, this requires well-processed print data to be provided in a PDF format.

More information on how to provide properly prepared print data can be found here.