To ensure a standard level of quality control, we have developed a system based on many years of experience dealing with different customer requirements. The primary goal of our quality management system is not only to meet, but ideally to exceed customer expectations. We are constantly improving our system in all areas to ensure a high level of quality throughout our company. Our process management complies with ISO 9001 certification and is outlined in detail in our guidelines and instructions.

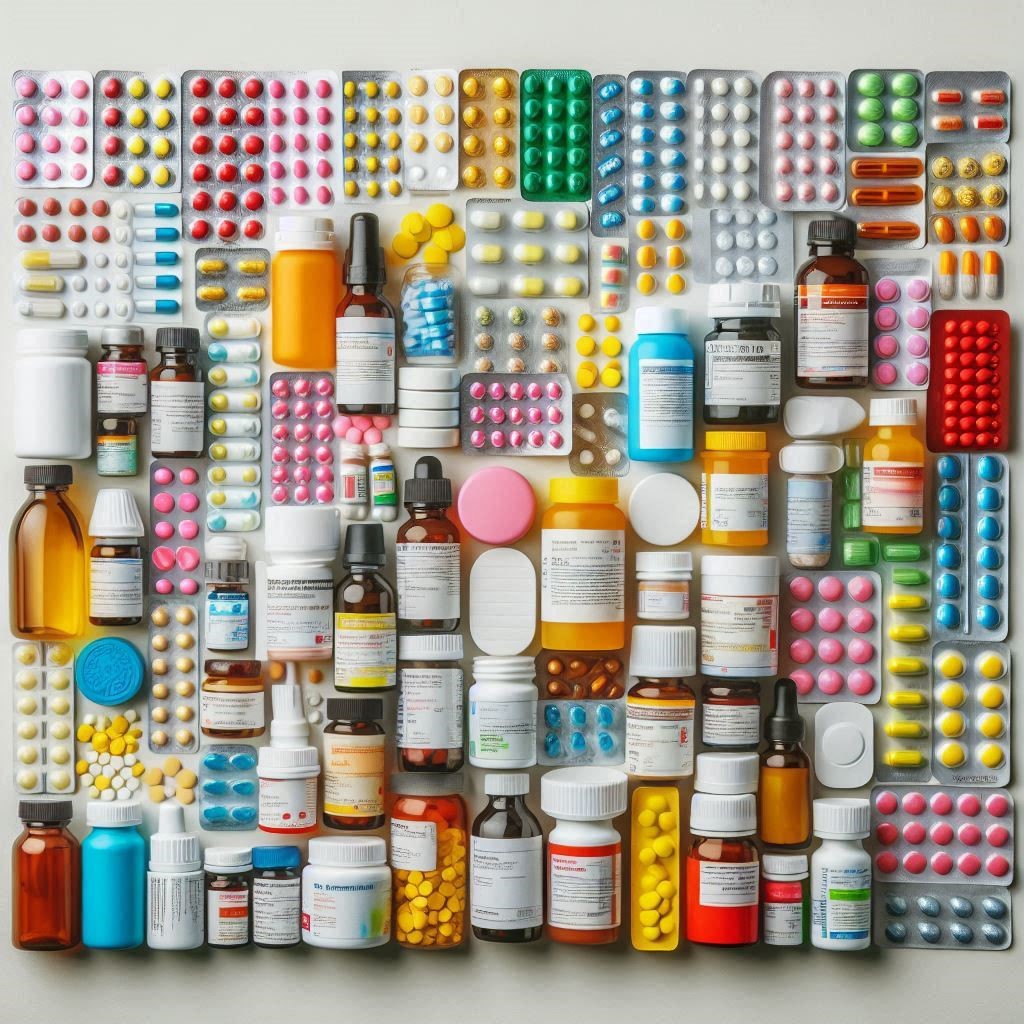

However, we also have customers for whom the basic ISO 9001 certification is not enough, and we have built an even higher level for these customers from the pharmaceutical industry. For these customers, we have developed specialized label production solutions that meet the stringent requirements of the pharmacy-segment. There is no room for variations or imperfections in the pharmaceutical sector. Even the slightest error can have serious consequences, which is why it is essential to pay the utmost attention to every step in the production process.

Pharma Production System

For customers in the pharmaceutical industry, we have developed a specific production system to ensure that all their individual requirements are met. The system includes regular customer audits, sampling during production, and an inter-operational inspection process. All processes are thoroughly recorded and logged to avoid any confusion or errors, from materials to output control.

100 % Quality Control of Production Output

Inspection is one of the key processes to which we pay particular attention. We have state-of-the-art inspection equipment that we have developed in collaboration with pharmaceutical manufacturers. As a result, we are able to inspect 100% of every label produced, including the verification of key label information during final production. At the same time, we provide label numbering to record usage and storage. Any label which does not match the specified parameters is immediately discarded.

Documentation

We maintain detailed documentation of the entire production process, which is archived together with samples for follow-up checks. In the event of any issues, we have all the information we need about the materials used, production batches, and when and by whom the individual processes were carried out.

If you wish to learn more about our pharmaceutical production possibilities, we would be happy to show you everything on site.